Needlepunch Manufacturing Process

The needlepunch manufacturing method creates a fabric like nonwoven from natural, synthetic and blends of fibers. Needlepunched nonwovens are very stable and are commonly used in automotive applications, in construction underlayments, geotextile applications, mattress, furniture and top of the bed products.

Large Bale Feeders

WIN processes millions of pounds of US grown cotton and US manufactured polyester fiber annually. The bale feeders begin the process of opening the fiber.

Small Bale Feeders

Several small bale feeders allow WIN to accurately blend fibers creating custom products for a wide variety of industries.

Fiber Card

Half the fiber passes over the top of the card exiting in a parallel pattern. The other half moves through the bottom exiting in a random pattern giving the batt tensile strength when joined at the end of the carding process.

The Crosslapper

The crosslapper distributes layers according to the programmed weight.

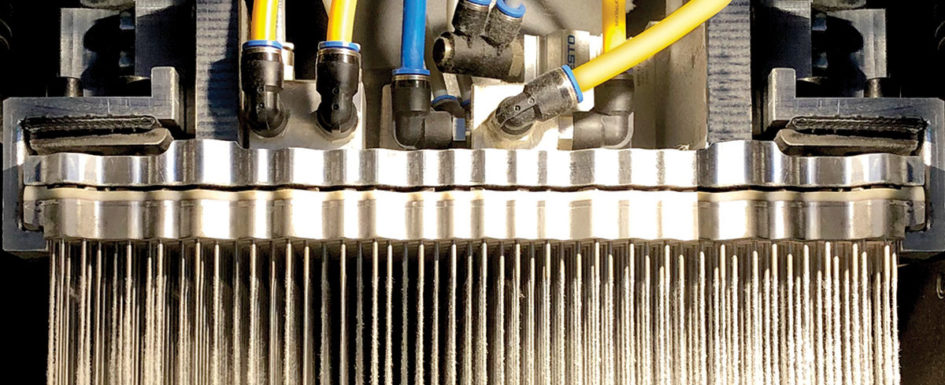

Needle Loom

The needle loom utilizes boards with thousands of 16″ barbed needles moving up and down at speeds of 800 to 2500 strokes per minute. The needles force the fiber down with the barb bringing the fiber back up entangling it to itself. WIN’s needlepunch lines include both up and down stroke boards achieving strong material with precise lofts and weights.

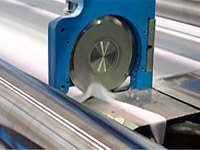

Edge Trim

1 – 2″ is trimmed from each edge to ensure accurate weight and width throughout the finished roll.

Weight, width and loft of every roll produced is documented ensuring specifications are met.